|

History of Swan Hunter

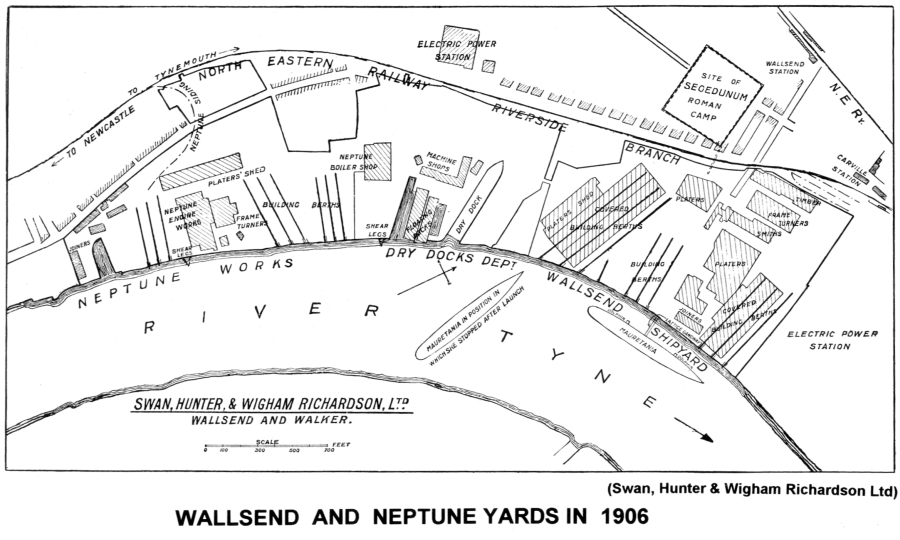

The Wallsend Yard early days In 1852 Charles Mitchell, who had been a ship designer with Mr Coutts, also started his own shipbuilding business at Walker. In 1854 he married the oldest daughter of Mr William Swan of Walker, an event of some importance to this story, since one result of the marriage was that two brothers of the bride, Henry Frederick and Charles Sheridan Swan, eventually joined the Mitchell undertaking. The business prospered to the extent that Mitchell was soon looking for additional space and to this end, in 1871, acquired a small site at St Peter's (further up-river towards Newcastle) where two of his associates began building ships under the style of Coulson, Cooke & Company. In 1873 this firm moved to a larger and more suitable site, some 6.5 acres in area, at the river-front of Wallsend and bordering the shipyard of Schlesinger, Davis & Company which had been opened in Wallsend Parish in 1863. About a year later however, in 1874, the firm ran into financial difficulties and it became necessary for Mitchell to take over the Wallsend shipyard. This he entrusted to the management of his brother-in-law, Charles Sheridan Swan, who continued the work of the firm through mixed fortune until his untimely, accidental death in 1879, when returning from the continent after a business trip, he fell from the bows of a paddle steamer and was struck and killed by one of the paddles. It was about this time however, that George Burton Hunter, a young Wearside shipbuilder who had earned a reputation on the North East Coast, had dissolved his partnership with a Mr SP Austin and entered into negotiations with Charles Mitchell and H F Swan. The outcome of this was a new partnership with Charles Swan's widow in the style of C S Swan & Hunter, with Hunter as managing director. George Burton (ultimately Sir George) Hunter, the grandfather of Sir John, who would later become the Chairman of the Swan Hunter Group, was a man of outstanding technical and commercial ability, whose interests extended far beyond his professional life. He associated himself with the interests of the Wallsend community, already expanding round the shipyard. He found congenial occupation with 'C S Swan & Hunter', being called upon to run this business almost single-handed until 1895, when he brought about a remarkable transformation in the Wallsend shipbuilding scene. When he took over, the yard covered less than seven acres, with a river frontage of less than one hundred yards. In 1883 he acquired the adjoining land of a chemical manufacturer amounting to some 16 acres, constructing upon it what was then known as the East Yard, making the company's total area for the two yards 23 acres, containing six building berths. In 1897 the company also acquired the recently defunct & adjoining shipyard of Schlesinger, Davis & Co which increased the Wallsend yard's total area by a further seven acres. The latter yard was re-equipped to handle a new type of construction for which the company then become famous - the construction of floating docks. In 1902, however, the Schlesinger Davis yard was reorganised for still more spectacular purposes, namely the preparation of two new building berths, 750 feet in length, for the construction of the largest types of ships. These would become the famous gantry crane berths, a Tyneside landmark for over 60 years, which were roofed in glass and fitted with seven electric gantry cranes. The Neptune Yard early days Historically a number of different dates suggest themselves as a starting point for the story of the Neptune Yard of Wigham Richardson & Co at Low Walker but it is generally accepted that it all began in 1860 when John Wigham Richardson, 23 years old son of a distinguished Yorkshire family of Quakers, armed with a little paternal capital and a brave desire to become a shipbuilder, purchased a small shipyard at Walker-on-Tyne. John Coutts had first laid down the Walker Shipyard in 1842 and had built what might be regarded as Britain's first steam collier, the Q.E.D. However, despite a promising beginning, Coutts' venture did not succeed. The yard was taken over by a London firm called Miller, Ravenhill and Salkeld but with no better results. John Wigham Richardson's business at his 'Neptune Works' began modestly enough. In 1860 the shipyard had three berths, covered no more than four acres of ground, had a river frontage of just over a hundred yards and gave employment to about 200 men. Wigham Richardson appointed as manager of his new enterprise another gifted young man named Charles John Denham Christie, the grandfather of one of the Directors of Swan, Hunter & Wigham Richardson Ltd until the formation of Swan Hunter Group Ltd. Together these two men, who eventually entered into partnership, steered the firm through many early difficulties. That the business eventually succeeded in stabilising itself was mainly due to Wigham Richardson's indefatigable questing for new orders, combined with Christie's first- rate knowledge of ship design and construction. In 1872, the firm began making its own marine engines and boilers, a new works for this purpose being erected to the North of the Shipyard. These works were extended in 1879 by the acquisition of neighbouring premises. Some time afterwards, the boiler works formerly attached to the engine works were removed to new premises further north and this occasioned an increase of nearly double its size for the machine shops and erecting shop of the engine works. This extension, together with two new building berths built to the north of the existing shipyard in the late 1880's, meant that Neptune Works now covered some 18.25 acres, with a river frontage of about 1,100 feet. In 1899 when it was decided to make the firm a limited company in the style of 'Wigham Richardson & Company Ltd' an extensive reputation had been gained for the construction of high class ships and particularly for those with specialist duties. Swan, Hunter & Wigham Richardson In June 1903 an amalgamation between C S Swan & Hunter Ltd and the neighbouring firm of Wigham Richardson & Company Ltd, operating the Neptune Shipyard and Engine Works at Walker formed the company of Swan, Hunter & Wigham Richardson Ltd. The new company acquired a controlling interest in the Wallsend Slipway & Engineering Company Ltd, marine engineers and ship repairers, situated some half a mile down-river to the east. Later in the same year the Tyne Pontoons & Dry Docks Company Ltd, whose installations lay between the Wallsend West Yard and Neptune Works, was purchased by the new company, to form what became to be known as the Dry Docks Department. This latter acquisition gave the company an unbroken river frontage of some 4,000 feet, and works covering nearly 80 acres. The 1903 amalgamation enabled the firm to contract for and build the famous MAURETANIA which held the Blue Riband for the fastest crossing of the Atlantic, for 22 years. Not only was the company now able to deal with all aspects of shipbuilding activity, namely, the design and construction of the hulls and machinery installations, but was able to concern itself with the repairs, overhauls and renewals necessary to keep ships in the highest condition to meet the demands of sea-going commerce. It was at this time that the works of Swan, Hunter & Wigham Richardson Ltd, began to take the form and appearance which they kept for the next fifty years.

Above map is courtesy of Norman L Middlemiss After the formation of 'Swan, Hunter & Wigham Richardson Ltd' in 1903 the firm went forward from strength to strength. In 1912, the company acquired Barclay, Curle & Co Ltd of Whiteinch, shipbuilders, repairers and engineers and also the Elderslie Dockyard at Scotstoun, both companies being on the River Clyde. Also in 1912 the company opened up a new yard in the Swan, Hunter & Wigham Richardson Ltd name at Southwick on the River Wear. This was a four berth yard to take up an excess of orders for tramps, colliers and Great Lake steamers.During WW1 the company contributed the full extent of its power to the construction, repair and conversion of all types of tonnage, naval and merchant to meet the ever increasing demands of the emergency. Between the wars, when many shipbuilding businesses succumbed to the difficult economic conditions prevailing at that time, the company continued to trade. By keen and competitive prices, by keeping abreast of and often sponsoring the latest technical developments and by the pursuit of forward looking policies by the Directors, the company maintained its position in the vanguard of shipbuilding enterprise. With the conclusion of WW2, when it became apparent that the shipbuilding industry in Britain was about to embark upon a massive replacement programme of shipping lost in that conflict, it also became clear that the layout and equipment of the shipyards would be inadequate if the Company were to remain at the forefront. The major reason for this was the technical change in production techniques when the steel structure of a ship was welded instead of riveted. This caused an evolution from the erection of the ship in single plates and bars to the construction of large prefabricated units. There are obvious advantages in doing a large percentage of the welding under cover with modern machine tools, one of the greatest being the continuous employment of the workforce concerned during the inclement weather, a factor which had caused the loss of a great deal of production time in the past while ships were being erected piece by piece on the 'open' berths. Another reason for complete re-organisation of shipyard layout was the tendency for the average size of various types of ships to increase. Although existing berths appeared to be adequately long, their comparatively narrow width was in many cases the deciding factor in the size of ship they could build, while the lifting facilities with which they were equipped were not suitable for modern methods of ship construction. In considering the reorganisation of both the yards, these problems had to be considered. In 1966 Swan Hunter & Wigham Richardson Ltd, merged with Smith's Dock Co Ltd which had a shipbuilding yard on the Tees and extensive ship repairing interests on the Tyne. The name of the new company became Associated Shipbuilders Ltd, and later Swan Hunter Group Ltd which, prior to nationalisation of the industry, was a holding company with subsidiaries in shipbuilding, ship repairing, engineering and civil engineering. Following the issue of the Geddes Report on the shipbuilding industry in 1966 discussions were opened with the owners of other shipyards on the Tyne on the subject of a possible merger of all the shipyards on the Tyne into one company. As a result, the Swan Hunter Group first acquired John Readhead & Sons Ltd and then merged with the Naval Yard of Vickers Ltd and R & W Hawthorn Leslie & Co Ltd. A new company, Swan Hunter & Tyne Shipbuilders Ltd was incorporated and all shipbuilding interests on the Tyne were transferred to the new company in January 1968. Subsequently the name was shortened to Swan Hunter Shipbuilders Ltd. In January 1969 Swan Hunter Shipbuilders took over the Furness Shipbuilding Co at Haverton Hill-on-Tees which had been scheduled for closure and a loss of 2,800 jobs. At that time Swan Hunter Shipbuilders Ltd owned and operated three shipyards on the north bank of the Tyne (ie Naval Yard at High Walker, Neptune Yard at Low Walker and Wallsend Shipyard) and two on the south bank of the Tyne, (ie Hawthorn Leslie Shipyard at Hebburn and Readheads Shipyard at South Shields) as well as the Haverton Hill Shipyard on the Tees. In addition, Swan Hunter Group Ltd of which Swan Hunter Shipbuilders was a wholly-owned subsidiary, owned the shipyard operated by Smith's Dock Co Ltd on the Tees and shipyards building smaller ships, i.e. fishing vessels, tugs, etc. at Goole on the Humber and at Willington Quay at Wallsend. In December 1969 Swan Hunter clinched on of the largest orders for merchant ships in the World at that time £44 million. The order was for four refrigerated container ships, each of which would be the largest of their type in the World. This order alone was would support 2,500 workers for over three years and would probably be split between the Tyne and Haverton Hill. The ships were to be run by a consortium of British shipowners to provide a premium service between New Zealand and the UK. Two of the ships were for Overseas Containers which included Shaw Saville Line and the New Zealand Shipping Company and the other two were for Associated Containers Transportation which included Port Line and Blue Star. But by May of 1971 this order was in tatters as increasing costs in setting up the infrastructure in the ports to handle these huge vessels made the whole operation unviable and in the end only one was built, REMUERA for the New Zealand Shipping Company being the one that was furthest progressed. See OCL-ACT order for more information. In 1973 Swan Hunter Shipbuilders acquired Palmers (Hebburn) from Vickers Ltd which contained two drydocks and between then and 1976 developed an entirely new shipbuilding complex named Hebburn Shipbuilding Dock (See technical paper on the development of these facilities HERE). The numbers employed in the Tyne shipyards of Swan Hunter Shipbuilders was approximately 11,500 and a wide variety of ship types were built by them, including cargo vessels, bulk carriers, crude oil tankers and container ships of all sizes. They also built Naval ships of varying types for the Ministry of Defence as well as fleet replenishment ships for British or foreign ownership. In the 5 years prior to nationalisation almost £16M was spent on modernising the yards owned by the company, including the cost of developing the new Hebburn Shipbuilding Dock. Much of the confidence to invest on this modernisation programme was based on an agreement struck with with Maritime Fruit Carriers in 1973 to build an initial 20 ships, which was projected to rise to some 50 ships in the near future. Unfortunately these contracts were in jeopardy within 2 years due to a collapse in the value of shipping and the financial problems of Maritime Fruit Carriers. See Maritime Fruit Carriers for the background on the rise and fall of the deal. On 1st July 1977 Swan Hunter Shipbuilders Ltd came under national ownership when in terms of the Aircraft & Shipbuilding Industries Act it became a member of the new Corporation named British Shipbuilders. The shipyards for which the operating company Swan Hunter Shipbuilders Ltd was made responsible to the Corporation were Wallsend Shipyard, Neptune Shipyard, Walker Shipyard, Hebburn Shipyard and Hebburn Shipbuilding Dock. The Wallsend Shipyard was the first in the world to construct tankers of over 250,000 tons on a slipway. The first of these VLCC's was launched in May 1969. The association of this yard with the Royal Navy commenced with the destroyer HOPE in 1909 and since then over 100 warships were built. Production also included the aircraft carriers ILLUSTRIOUS and ARK ROYAL. The yard also possessed one of the most up-to-date steel working facilities in the shipbilding world at the time, opened in December 1971 it produced flat stiffened panels to a maximum weight of 100 tons for use in all Swan Hunter Shipbuilders Shipyards. However the end of the Maritime Fruit orders and falling orders elsewhere meant that facilities had to contract and yards had to close and the South Shields yard was the first in 1977. In 1979 at Hebburn Shipyard, No 1 berth and some shop facilities were integrated with the Hebburn Shipbuilding Dock facility. The remainder of Hebburn Yard ceased shipbuilding operation and became the base for a new training shipyard school for the North East of England. In 1980 construction of ships ceased at Walker Shipyard, but the yard facilities were developed to establish the yard as an outfitting base for ships that would be transferred from the remaining three shipyards. The remainder of the shipyard at Walker would be put on care and maintenance basis. Swan Hunter Shipbuilders Ltd then consisted of the four shipyards on the Tyne; Wallsend Shipyard, Neptune Shipyard, Hebburn Shipbuilding Complex and Walker Shipyard. The centralised Joinery Workshop at Wallsend Shipyard produced all panel and specialist furnishing for all the yards. Although construction of ships at Walker has since ceased, it was developed as an outfitting centre for the other new building yards. The Centralised Blacksmiths Production Facilities and the Central Accounts Department for Swan Hunter Shipbuilders at that time were based at Walker. The newly formed Tyne Regional Computing Centre, that provided computer facilities to Swan Hunter Shipbuilders and other shipbuilders in the region, was located at Walker Shipyard. In 1987 the company was privatised again but the Neptune Yard was closed in the following year. Trading conditions remained difficult in the early 1990's and further closures followed, but the company remained profitable. However in 1993 an important Government contract wass awarded elsewhere and when the company then had a cashflow issue the banks refused further credit and Swan Hunter was put into the hands of the receiver. In 1995 Swan Hunter (Tyneside) Ltd was established by Mr Jaap Kroese who then acquired the shipyard which then diversified into offshore oil & gas construction as well as naval shipbuilding. For the next decade under his stewardship the company was successful in obtaining both offshore vessel conversion work, including the conversion of a bulk carrier into the world's largest pipelaying vessel the SOLITAIRE as well as new buildings for the Royal Navy in the form of the LSDs LARGS BAY and LYME BAY. However, with no fresh orders after 2007 and severe competition from Far East shipyards, the yard construction facilities were eventually closed down and the majority of the land sold to the North Tyneside Council and One NorthEast in 2009. However, Swan Hunter still continues to operate but now only in the design and engineering field, providing design and management support to shipyards and ship owners via the engineering group that still occupies the management offices on the site. |