|

The best known heavy engineering firm of old Gateshead was, of course, Hawks, Crawshay & Sons. The firm was started in 1748 by William Hawks, at New Greenwich on the South Shore. Hawks had been a foreman blacksmith at Crowley's works and he named his first factory after Crowley's old premises at Greenwich on the Thames. William Hawks II took control of the firm in 1775 and expanded his premises and trade, foundries were bought and steam introduced. By 1801 the firm produced several kinds of ordnance, anchors, chains, bolts, spades and many other metal products. Government contracts were taken over from the declining firm of Crowley and the stage was set for a successful period of trade, helped by the Napoleonic wars and therefore a constant demand for weapons. The new premises were known as New Deptford and New Woolwich, built to the west of the older works. (Hawks' had warehouses on the Thames at these places.) By the end of the eighteenth century this by now prosperous concern had its own ships to transport its goods.

In 1839, Hawks' employed approximately 800 men and boys. Skilled tradesmen earned 22 shillings per week while labourers were paid 2 shillings per day. An investigation was made into the working conditions of children in the works in 1842 and the following example illustrates the hard life these children led. One twelve-year-old boy had already worked at Hawks' factory for 3 years. His hours were 6.00 am to 6.00 pm (summer; one and a half hours for meals), and 6.00 am to 5.00 pm (winter; 45 minutes for meals). On Saturdays work ended at 400 pm. This particular boy was paid 4 shillings per week for carrying iron to furnaces and his ambition was to be apprenticed as a chain-maker at a wage of 6 shippings per week. The only holidays were 2 days at Christmas and 2 half days at Easter and Whitsuntide. As at Crowleys, the employees of Hawks had certain benefits; schools for workers and their children, houses provided by the firm and a code of rules with fines for swearing, betting and drinking. Despite the hard work, very low wages and long hours (all were typical of the period),'Haaks' men' were apparently contented workers. The firm began to design and build many different products ranging from paddle steamers to dredgers and from bridges to lighthouses. Everyone has heard of the High Level Bridge, built by Hawks' 1846-49, but they also constructed iron bridges as far afield as Constantinople and India. However impressive these achievements may sound they were the cause of the closure of the company, coupled with the incompetence of George Crawshay, a partner in the firm. Specialist manufacturers expanded and were more successful than a firm such as Hawks which tried to make everything. The Armstrong works for example, at Elswick were divided into specialist departments while William Galloway, the nail manufacturer, became a force to be reckoned with in that single branch of the iron trade. Hawks, Crawshay and Sons (the firm had many changes of name and this was the last) closed suddenly in September 1889, but every creditor was paid in full and today this name remains a proud reminder of Gateshead's industrial past. Extracted from "A Short History of Gateshead" © Gateshead Metropolitan Borough Council, 1998 |

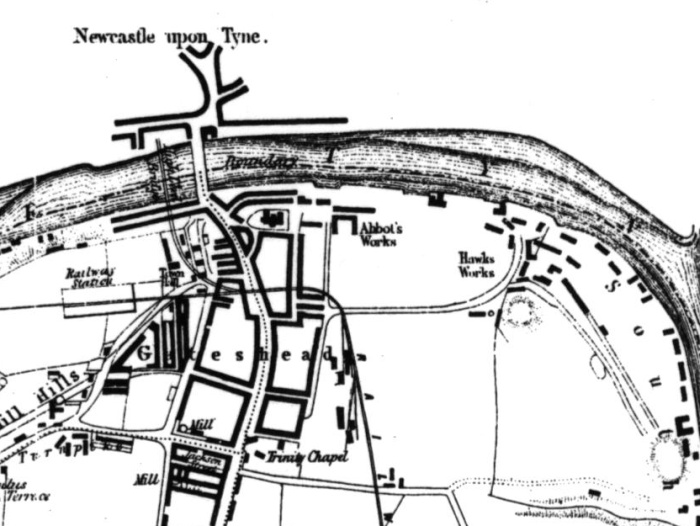

Above map shows the Hawks Works to the right of centre

UNDER CONSTRUCTION

USE BROWSER BACK BUTTON TO RETURN